Drake Labs cuts custom shoe manufacturing time by 30%

Customer

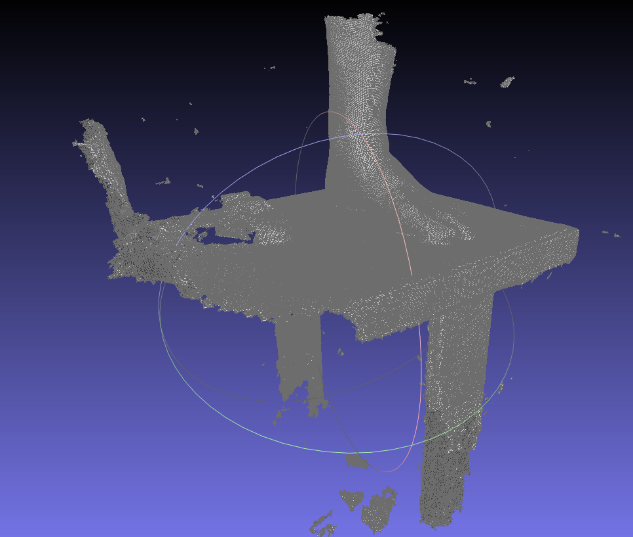

Drake Labs manufactures precision fit 100% customized carbon footwear. The company aims to provide customized precision-fit carbon footwear for athletes. They scan the feet using iPhone true depth camera to get point cloud data of the feet. Customized carbon footwear is created by processing the scan data.

Name: Drake Labs

Industry: Consumer Goods

Location: Seattle, Washington, USA

Challenges

- Feet scan data provided by the customer have lots of noise and holes

- Align the scan to XYZ coordinate and extract the feet from the scanned data

- Scanned data was not directly usable for print without processing

- It used to take lots of time and effort to align the scan to XYZ coordinate before cropping, clean-up, scaling, hole filling, and creating an STL file for shoe printing

- The customer needs this process to be automated and should not take more than 5 minutes

Solution

- Developed a state-of-the-art algorithm to create a high-quality feet surface mesh from scanned data automatically

- Software was implemented using C++ and Python

- Tool is used as a command line that takes the raw scanned file and produces the final STL file for 3D printing after aligning the scan, clean-up, crop, scale, and hole filling

Results

- Fully automated process to reconstruct 3D model from scanned data with noise and gaps/holes due to missing data

- Reduced the time it takes to clean up the scanned data from days to minutes

- Automated process, which takes less than 5 minutes to complete

- The result is a high-quality surface mesh that can be used for 3D printing